Article #39: Parallel and Series

Operation of Pumps, and Operating against Multiple Systems

In most training exercises or general discussions of

pump-system interactions, great simplifications are made. The two most common

examples presented are usually two pumps operating in parallel, or two pumps

operating in series. Rarely, discussion involves more then two pumps, and even

less frequently operation of a single pump against a multi-branched system is

discussed. Yet, real installations rarely resemble such isolated and greatly

simplified situations. Usually, in practice, multiple pumps operate against

multiple branches of a system, or several interconnected complex systems

operated with pumps coming on and off line, valves adding multiple new

branches, or shutting off parts of the system.

Such multi-branched, multi-pump systems can no

longer be analyzed with a graph and calculator in hand, but an entire

computerized network of the plant piping, tanks, pumps, reflecting proper

sizes, friction, elevations, and so on, need to be carefully modeled.

However, before the complexities of the entire plant

modeling are attempted, the fundamentals of the multi-pump, multi-branch

systems must be first understood. When such examination is reviewed, it becomes

clear that the entire complex network is essentially a combination of the

following three cases:

- Several pumps in parallel, against a single system

- Several pumps in series, against a single system

- A single pump against two-branched system, or against a multi-branched

system

This article presents the fundamentals of such three

main building blocks of the complex network.

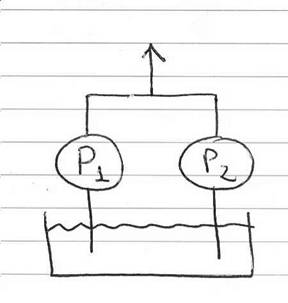

1-a: (2) pumps in parallel against (1)

system

1-b: (2) pumps in series – against (1) system 1-c: (1) pump – against (2) system

branches

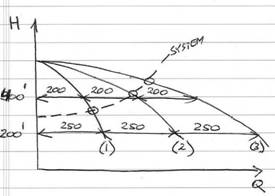

1-a: (2) pumps in parallel against (1)

system

Method of

construction of multiple (combined) pump curve: at constant head line (200’)

double the flow (250 gpm x 2) for a point on a 2-pump curve. Repeat at several other

constant head lines, such as at 400’ double the flow (200 gpm x 2). For 3-pump

operation, triple the flow at constant head lines. Continue in the same fashion

for more pumps. Intersections between one, two, three, or more pumps, with a

given system curve establishes operating point (resultant head and flow) for

multiple pumps.

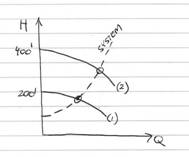

1-b: (2) (or more) pumps (or pump stages)

in series – against (1) system

Method of

construction of multiple (combined) pump curve: at series of constant flows,

add pump (or pump stages for multiple pumps) heads. Intersections between the

result pump curve (stages curve) and a system curves establishes operating

point (resultant head and flow).

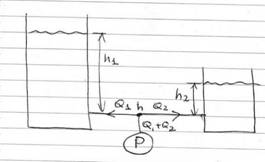

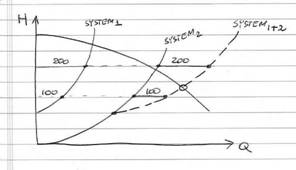

1-c: (1) pump – against (2) system branches

Method of construction:

instead of combining pump curves, add flows (at constant head) for systems (can

be more then two). Intersection of the resultant system curve with a given pump

curve produces operating point (resultant flow and head)

This process

can be computerized as illustrated in a simplified example of a positive

displacement pump operating against two systems (two branches). Underlying

programming formulas are:

(1) H = h1 +

k1 x Q12 – general equation for a system of

branch (1), including static head h1 and friction with system friction

resistance k1

(2) H = h2 +

k2 x Q22 – general equation for a system of

branch (2), including static head h2 and friction with system friction

resistance k2

(3) Q = Q1 +

Q2 – what leaves the pumps splits into branches

Known/given:

Q, k1, k2, h1, h2

Need to

find: Q1, Q2 and pump head h

Programming procedure:

- Guess h

- Calculate Q1 from (1)

- Calculate Q2 from (2)

- Calculate Q=Q1+Q2 and compare with given Q

- If calculated flow is different then given,

re-guess h and repeat the process until error is small

Click: 2-branched

system with 1-pump: sample

Only when these

fundamental basics of the pump(s)-to-system(s) principles are understood, you are

ready to take the next step – a computerized analysis of complex pumping

systems.