Article

#7: Lubrication Practices: How Grease-Lubricated Bearings Function

A

shielded, grease-lubricated ball bearing can be compared to a centrifugal pump

having the ball and-cage assembly as its impeller and having the annulus

between the stationary shield and the rotating inner race as the eye of the

pump.

Shielded

bearings are not sealed bearings. With the shielded type of bearing, grease may

readily enter the bearing, but dirt is restricted by the close fitting shields.

Bearings of the sealed design will not permit entry of new grease, whereas with

shielded bearings grease will be drawn in as the bearing cage assembly rotates.

The grease will then be discharged by centrifugal force into the ball track of

the outer race.

If

there is no shield on the backside of this bearing, the excess grease can

escape into the inner bearing cap of the equipment bearing housing.

Single-shield bearings

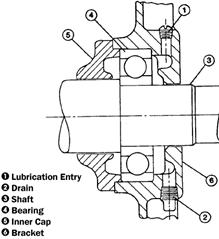

Plants

applying best-in-class-practices today consider the regular single shield

bearing with the shield facing the grease supply (Figure 7-1) to be the best

arrangement. Their experience indicates this simple arrangement will extend

bearing life. It will also permit an extremely simple lubrication and

relubrication technique if so installed.

This

technique makes it unnecessary to know the volume of grease already in the

bearing cartridge. The shield serves as a baffle against agitation. The

shield-to-inner-race annulus serves as a metering device to control grease

flow. These features prevent premature ball bearing failures caused by

contaminated grease and heat buildup due to excess grease. Further, warehouse

inventories of ball bearings can be reduced to one type of bearing for the

great bulk of existing grease-lubricated ball bearing requirements. For other

services, where an open bearing is a "must," as in some flush-through

arrangements, the shield can be removed in the field.

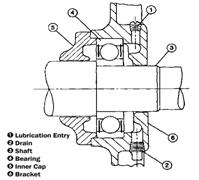

Figure 7-1 Single-shielded equipment bearing,

with the seal facing the grease cavity

Double-shielded bearings

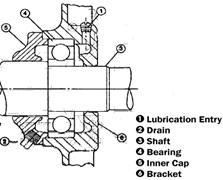

Some

manufacturers still subscribe to a different approach, having decided in favor

of double-shielded bearings. These are usually arranged as shown in Figure 7-2.

The housings serve as a lubricant reservoir and are filled with grease. By

regulating the flow of grease into the bearing, the shields act to prevent

excessive amounts from being forced into the bearing. A grease retainer

labyrinth is designed to prevent grease from reaching the inner side of the

bearing.

Figure 7-2 Double Shielded bearing with

grease. Metering plate facing the grease reservoir

On

equipment furnished with this bearing configuration and mounting arrangement,

it is not necessary to pack the housing next to the bearing full of grease for

proper bearing lubrication. However, packing with grease helps to prevent dirt

and moisture from entering. Oil from this grease reservoir can and does, over a

long period, enter the bearing to revitalize the grease within the shields.

Grease in the housing outside the stationary shields is not agitated or churned

by the rotation of the bearings and consequently, is less subject to oxidation.

Furthermore,

if foreign matter is present, the fact that the grease in the chamber is not

being churned reduces the probability of the debris contacting the rolling

elements of the bearing.

On

many pieces of equipment furnished with grease-lubricated double-shielded

bearings, the bearing housings are not usually provided with a drain plug. When

grease is added and the housing becomes filled, some grease will be forced into

the bearing. At this point any surplus grease will be squeezed out along the

close clearance between the shaft and the outer cap because the resistance of

this path is less than the resistance presented by the bearing shields,

metering plate, and the labyrinth seal.

Open bearings

High-load

and/or high-speed bearings are often supplied without shields to allow cooler

operating temperature and longer life. One such bearing is illustrated in

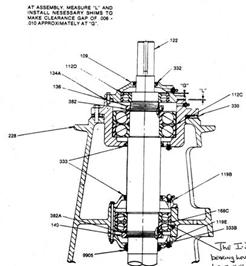

Figure 7-3.

Figure 7-3 High load/ high speed bearings are

often supplied without shield

If

grease inlet and outlet ports are located on the same side, this bearing is

commonly referred to as "conventionally grease lubricated." If grease

inlet and outlet ports are located at opposite sides, we refer to

"cross-flow lubrication." Figure 7-4 shows a cross-flow lubricated

bearing.

Figure 7-4 Open bearing with cross flow

grease lubrication

Lifetime lubricated,

"sealed" bearings

Lubed

for-life bearings incorporate close-fitting seals in place of, or in addition

to shields. These bearings are customarily found on low horsepower equipment or

on appliances, which operate intermittently.

Although

a large petrochemical company in West Virginia has expressed satisfaction with

sealed ball bearings in certain equipment applications as long as bearing

operating temperatures remained below 150o C. (300o F) and speed factors DN (mm

bearing bore times revolutions per minute) did not exceed 300,000. Close-fitting

seals can cause frictional heat and that loose fitting seals cannot effectively

exclude atmospheric air and moisture, which will cause grease deterioration.

Procedures for Re-Greasing

Equipment Bearings

Rotating

equipment bearings should be re-greased with grease, which is compatible with

the original charge. It should be noted that the polyurea greases often used by

the equipment manufacturers may be incompatible with lithium base greases.

Single-Shielded Bearings

To

take advantage of single-shield arrangements, Phillips Petroleum developed

three simple recommendations:

1.

Install a single-shield ball bearing with the shield facing the grease supply

on equipment having the grease fill and-drain ports on that same side of the

bearing. Add a finger full of grease to the ball track of the backside of the

bearing, during assembly.

2.

After assembly, the balance of the initial lubrication of this single-shielded

bearing should be done with the equipment idle. Remove the drain plug and pipe.

With a grease gun or high volume grease pump, fill the grease reservoir until

fresh grease emerges from the drain. The fill and drain plugs should then be

reinstalled and the equipment is ready for service.

It

is essential that this initial lubrication not be attempted while the equipment

is running. It was observed that to do so would cause, by pumping action, a

continuing flow of grease through the shield annulus until the overflow space

in the inner cartridge cap is full. Grease will then flow down the shaft and

into areas where it is not wanted. This will take place before the grease can

emerge at the drain.

3.

Relubrication may be done while the equipment is either running or

idle.

(It should be limited in quantity to a volume approximating one-fourth the

bearing bore volume.) Test results showed that fresh grease takes a wedge-like

path straight through the old grease, around the shaft, and into the ball

track. Thus, the overflow of grease into the inner reservoir space is quite small

even after several relubrications. Potentially damaging grease is thus kept

from the stator winding, in motors. Further, since the ball and cage assembly

of this arrangement does not have to force its way through a solid fill of

grease, bearing heating is kept to a minimum. In fact, it was observed that a

maximum temperature rise of only 20 o F. occurred 20 minutes after the grease

reservoir was filled. It returned to 5 o F rise two hours later. In contrast,

the double-shield arrangement caused a temperature rise of over 100 o F (at 90

o F ambient temperature the resulting temperature was 190 o F.) and maintained

this 100 o F rise for over a week.

Double-Shielded Bearings

1. Ball Bearings

A. Pack (completely fill) the cavity adjacent

to the bearing. Use necessary precautions to prevent contaminating this grease

before equipment is assembled.

B. After assembly, lubricate stationary

equipment until a full ring of grease appears around the shaft at the relief

opening in the bracket.

2. Cylindrical Roller

Bearings

A. Hand pack bearing before assembly.

B. Proceed as outlined in (1) and (2) for

double shielded ball bearings.

If

under-lubricated after installation, the double shielded bearing is thought to

last longer than an open (non-shielded) bearing given the same treatment

because of grease retained within the shields (plus grease remaining in the

housing from its initial filling).

If

over-greased after installation, the double-shielded bearing can be expected to

operate satisfactorily without overheating. This will be as long as the excess

grease is allowed to escape through the clearance between the shield and inner

race, and the grease in the housing adjacent to the bearing is not churned,

agitated and caused to overheat.

It

is not necessary to disassemble equipment at the end of fixed periods to grease

bearings. Bearing shields do not require replacement.

Double-shielded

ball bearings should not be flushed for cleaning. If water and dirt are known

to be present inside the shields of a bearing because of a flood or other

circumstances, the bearing should be removed from service.

All

leading ball-bearing manufacturers are providing reconditioning service at a

nominal cost when bearings are returned to their factories. As an aside,

reconditioned ball bearings are generally less prone to fail than are brand new

bearings. This is because grinding marks and other asperities are now burnished

to the point where smoother running and less heat generation are likely.

Open Bearings

Equipment

with open, conventionally greased bearings is generally lubricated with

slightly different procedures for drive-end and opposite end bearings.

Figure 7-5 Double-Shielded Bearings

1. Lubrication procedures for drive-end bearings

A. Relubrication with the shaft stationary is

recommended. If possible, the equipment should be warm.

B. Remove plugs and replace with grease

fitting.

C. Remove large drain plug when furnished

with the equipment.

D. Using a low pressure, hand operated grease

gun, pump in the recommended amount of grease, or use 1/4 of bore volume.

E. If purging of system is desired, continue

pumping until new grease appears either around the shaft or at the drain

opening. Stop after new grease appears.

F. On large equipment provisions have usually

been made to remove the outer cap for inspection and cleaning. Remove both rows

of cap bolts. Remove, inspect and clean cap. Replace cap, being careful to

prevent dirt from getting into bearing cavity.

G. After lubrication allow the equipment to

run for fifteen minutes before replacing plugs.

H. If the equipment has a special grease

relief fitting, pump in the recommended volume of grease or until a one-inch

long string of grease appears in any one of the relief holes. Replace plugs.

I. Wipe away any excess grease which has

appeared at the grease relief port.

2. Lubrication procedure for bearing opposite drive end

If bearing hub is accessible, as in smaller

equipment with large couplings or drip-proof equipment, follow the same

procedure as for the drive end bearing. For fan-cooled equipment note the

amount of grease used to lubricate shaft end bearing and use the same amount

for commutator-end bearing.

Motor

bearings with grease inlet and outlet ports on opposite sides, are called

cross-flow lubricated. Regreasing is accomplished with the equipment running.

The following procedure should be observed:

2.1.

Start equipment and allow to operate until normal equipment temperature is

obtained.

2.2

Inboard bearing (coupling end):

A. Remove grease inlet plug or fitting.

B. Remove outlet plug. Some equipment designs

are equipped with excess grease cups located directly below the bearing. Remove

the cups and clean out the old grease.

C. Remove hardened grease from the inlet and

outlet ports with a clean probe.

D. Inspect the grease removed from the inlet

port. If rust or other abrasives are observed, do not grease the bearing. Tag

equipment for overhaul.

E. Bearing housings with outlet ports: (1)

insert probe in the outlet port to a depth equivalent to the bottom balls of

the bearing; (2) replace grease fitting and add grease slowly with a hand gun.

Count strokes of gun as grease is added; and (3) stop pumping when the probe in

the outlet port begins to move. This indicates that the grease cavity is full.

F. Bearing housings with excess grease cups:

(1) replace grease fitting and add grease slowly with a handgun. Count strokes

of gun as grease is added and (2) stop pumping when grease cavity is full.

3. Outboard bearing (fan end):

a.

Follow inboard bearing procedure provided the outlet grease ports or excess

grease cups are accessible,

b.

If grease outlet port or excess cup is not accessible, add 2/3 of the amount of

grease required for the inboard bearing.

c.

Leave grease outlet ports open-do not replace the plugs. Excess grease will be

expelled through the port.

d.

If bearings are equipped with excess grease cups, replace the cups. Excess

grease will expel into the cups.

Lev

Nelik

Pumping

Machinery, LLC

Some additional feedback from the professionals

in the field:

Roy A. Forson, CLS

Maintenance Manager

Imerys Performance Minerals :

Type A: The proper bearing re-lubrication with a drain plug is:

- Check

Temperature

- Wipe

grease fitting

- Remove

purge plug and clean out hard grease (unit must be down. If you cannot

take the top cap off, then insert small spoon-type tool and feel for hard

grease. If no hard grease is found, then continue below.

- Check

seals for excessive grease (blown seals, cracked seals. These should be

replaced)

- Pump

new grease until new grease exits out of the purge plug drain.

- Run

unit with purge plug removed for 10-30 minutes. (This will allow the

grease to equalize)

- Clean

and replace the purge plug.

Type B: The proper bearing re-lubrication without a drain plug

is:

- Check

temperature

- Shut

down & immediately remove grease fitting to allow the bearing to

self-purge

- Clean

and replace the fitting

- Pump

a limited quantity of grease to avoid rupturing the grease seal

- Remove

the fitting and allow for equalization

- Repeat

until grease comes out

- Replace

grease fitting

Type C: The proper bearing re-lubrication with a relief fitting

is:

- Check

temperature

- Clean

fitting and pump grease until it relieves

- If

it doesn't relieve, fitting may be plugged. Remove and replace

- Run

and check for relief/temperature

Additional general considerations for re-lubrication

of bearings other than electric motor bearings:

(Remember,

if you are not going to use any calculation for re-greasing, then you are

guessing)

1. If unit is running, check

temperature of all bearing surfaces. It is important to know if it's running

hot.

2. Using all safety precautions,

locate grease fitting and clean the fitting of debris by wiping it off with a

clean rag.

3. Verify the type of grease in the

grease gun - do not take for granted that what is marked on the pump is what's

in the pump.

4. Pump a little bit of grease out of

the gun and wipe the end. This will remove any debris trapped in the nozzle

5. Install the end of the grease

nozzle onto the grease fitting and verify it is on properly

6. Pump grease into the bearing based

on the plant "grease amount" recommendations.

Caution - if grease will not

pump into the bearing, the grease fitting is probably bad (check valve probably

stuck)

7. Observe the seal of the bearing

and be sure not to over-grease. Over-greasing will cause the seal to open,

consequently breaking the seal.

8. After greasing, listen for any

unusual sounds.

There are more technical instructions for the serious user like calculating re-lubrication

amounts based on bearings size, re-greasing frequencies based on bearing size,

speed, conditions, etc.

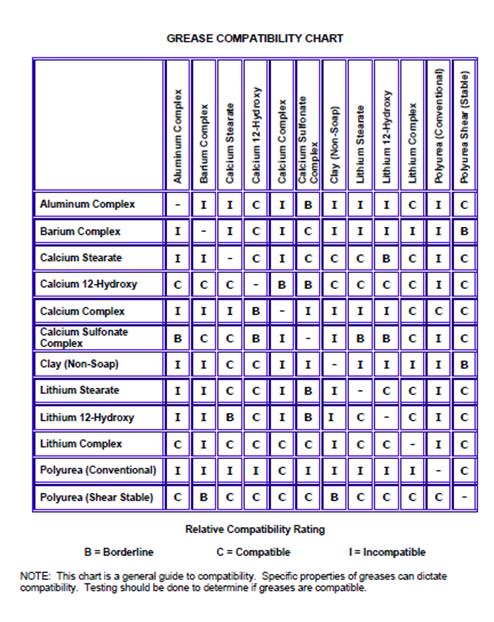

Know the thickener type. If grease tube mentions polymers - these are additives that can improve things

like increase base oil viscosity and increase adhesiveness and really have

little to do with compatibility. The thickener type is most important. Some

thickeners are not compatible with others. For example, aluminum is not

compatible with lithium, polyurea is not compatible with most thickeners,

barium, clay, calcium thickeners are not compatible with other types. Some of

the complex mixes are compatible, but you really have to know what it is your

are commingling. My advice is to conduct a compatibility test in a lab. Also,

when mixing two incompatible thickeners, you may get one of two typical reactions

- a soft and soupy solution where the grease does not stay put, or you can get

a rock hard material in the bearing housing. This occurs when the oil leeches

from the grease and all that remains is the thickener.

Additionally, remember grease is comprised of three components -

base oil, thickener, and additives. 85% of the three components is oil so it's

important to know what type of oil is being used, mainly synthetic.

Sorry to be long winded, but most places I use to go to have no

idea of the differences in greases. In many cases, a salesman will try to sell

you something and tell you it's compatible, but he really may not know.

Roy A. Forson, CLS

Maintenance Manager

Imerys Performance Minerals

To learn more about this topic, e-mail your comments to us at: